Heat Exchanger for Exhaust Heat Recovery

(For industry)

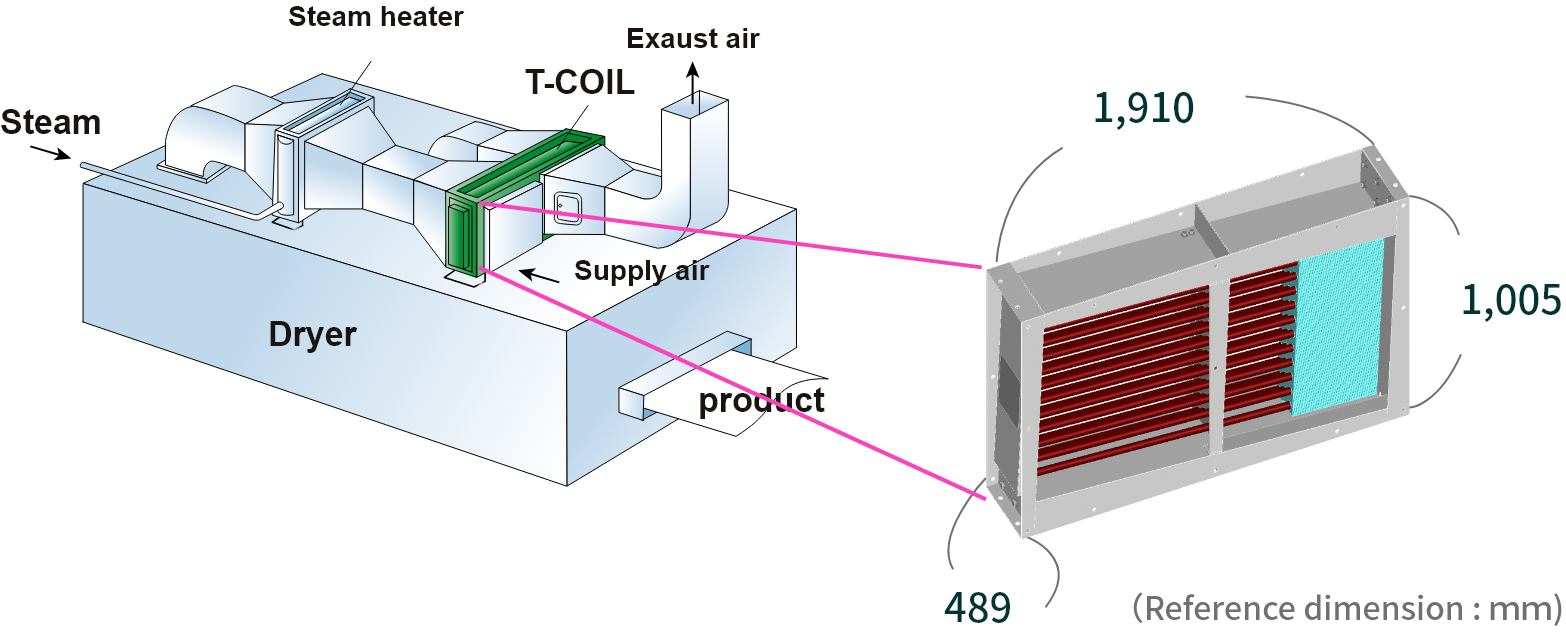

How to use the Exhaust Heat Recovery of T-COIL

BEFORE

Supply air(20℃) is heated and products are dried. After the air is used,the used air(100℃) is exhausted without heat recovery.

AFTER

T-COIL preheats Supply air(20℃) by the heat that T-COIL recovered from Exhaust air(100℃).

4 features of T-COIL

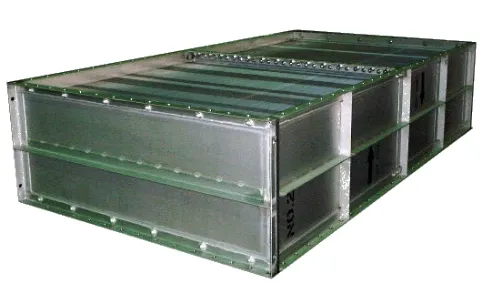

1Hight Efficiency, Space Saving

T-COIL recovers heat from exhaust air efficiently with using heat pipes as heat conductive elements.

It shows more than 50% temperature efficiency and does not need much space to be installed.

Air Preheating for a dryer

- BEFORE

- AFTER

-

Supply Air Exhaust Air Flow Rate(Nm3/min) 100 100 Inlet Temp.(℃) 20 100 Efficiency(%) 50 50

2Maintenance Saving、No Running Cost

The mechanical trouble does not occur and the parts replacement is unnecessary because T-COIL has no moving parts. T-COIL saves maintenance. Besides , the running cost of T-COIL is not required because it dose not use electricity to work.

3Long Life

T-COIL can be used for a long time because it is made of best materials that depend on the air property. Many T-COILs have been working all over the place for more than 30 years.

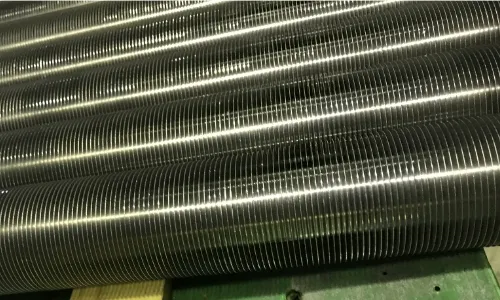

- Materials

-

- Fins/Tubes

- Aluminum、Copper、Steel、Stainless steel

- Flame

- Steel、Stainless steel

-

Aluminum fin tubes

-

Stainless steel flame

-

Steel fin tubes

4Clean Supply Air

T-COIL is partitioned off into two parts(supply air part and exhaust air part) by center plates. The good point of T-COIL is that exhaust air leaks to supply air very little. The supply air that is heated by T-COIL goes to a dryer with keeping air fresh.

T-COIL helps you to promote

Sustainable Development Goals by saving energy.

T-COIL achieves energy-saving efficiently

for a long time in spite of saving the maintenance and running-cost.